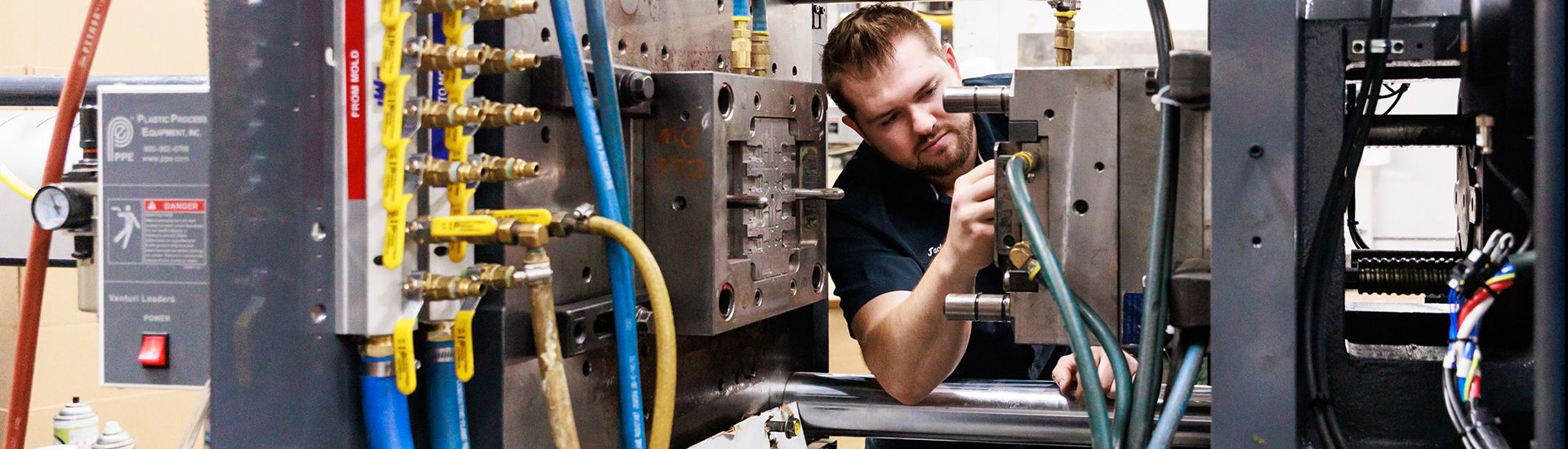

From prototype to full production, the team at Action Plastics will take the time to understand our customers products and their unique needs, allow us at Action Plastics to lead with flexibility and efficiency, proceed with accountability and end with mistake-proof products in hand. Whether low- to mid-volume runs, or one million+, we are well-equipped to give each project the critical attention it deserves.

To achieve this Action Plastics employs:

- Advanced development phase mold simulations and optimization

- Pre-production mold and process validation

- Production launch quality control techniques and instrumentation

- Ongoing supply chain management

The markets we primarily serve are:

- Off-road/Powersports

- Recreation

- Consumer goods

- Medical components

- Construction

- Aerospace and Defence

We utilize 28 hydraulic and electric molding presses along with:

- Four compartment gravimetric feeder systems

- Automated conveyor systems

- Robotics and Pickers

- Continuous quality inspection

- Clean room molding

- Regrind and Recycled content

Our injection capabilities include:

- Insert molding

- Over molding

- Robotic assist

- Single cavity prototypes through high-cavitation production molding

We support many industries including:

- Agriculture

- Industrial

- Consumer goods

- Packaging

- Medical components

- Aerospace

- Defense

- Off road and recreation

- Electronics